Hey, you!

I know you came for our awesome blog post, but we have to let you in on something. Our main business is a shop that sells a ton of unique and cool lifestyle and personal accessories made with REAL carbon fiber.

If you love carbon fiber as much as we do, go explore!

Everything we make leaves some carbon footprint.

Imagine a manufacturing process of car parts where raw materials like carbon fiber are extracted, processed, and transported, requiring a great deal of many other separate components, energy, and fuel. Even when these car parts have already reached their lifespan, we need more energy and fuel to dispose of them.

But what if carbon fiber never has to end up being dumped in the landfill and, instead, gets a new life with a new application somewhere else?

Join us as we delve into McLaren’s groundbreaking approach to turning their F1 cars into fully circular ones, redefining speed with sustainability in the industry. This approach was tested in the latest US Grand Prix in October 2023, showing impressive results.

RELATED: Recycling Carbon Fiber | Inexpensive and Sustainable Solution to the End-of-life Dilemma

In This Article:

- Why Recycled Carbon Fiber for McLaren F1?

- How is Recycled Carbon Fiber Made?

- Is Recycled Carbon Fiber as Good as New?

- How Did McLaren F1 Perform at the US GP?

- Outlook

McLaren Shows Pioneering Effort to Drive Sustainability and Zero Waste on F1 Tracks

Why Recycled Carbon Fiber for McLaren F1?

Manufacturing an F1 car like the McLaren MCL60 is an intricate process that significantly contributes to its carbon footprint. Recognizing the environmental impact, McLaren F1 has embraced recycled carbon fiber as a groundbreaking solution.

The decision stems from the pursuit of sustainability, acknowledging that the traditional manufacturing processes need to be reimagined to reduce the environmental impact of F1 racing. Two compelling statistics underscore the importance of this shift:

- First, recycled carbon fiber reduces life cycle emissions by a staggering 90%, translating to a saving of 27 tons of carbon emissions for each ton of material used.

- Second, with global demand for carbon fiber expected to reach 262,000 tons by 2025, even a 1% shift towards recycled carbon fiber could save 70,848 tons of carbon emissions.

This change is a significant step toward mitigating the environmental impact of F1 racing, showcasing the potential for minor changes to become zero waste. Such a substantial reduction is commendable in a world where carbon emissions are a growing concern.

The move toward recycled carbon fiber aligns with McLaren’s broader sustainability goals. While ambitious long-term targets are already set, the team recognizes the importance of incremental improvements and innovations in the short term.

By adopting recycled carbon fiber, McLaren is setting an example for the broader market and inspiring positive changes in the industry.

RELATED: Carbon Fiber Recycling | How Boeing Turns Scraps Into Better Use

How is Recycled Carbon Fiber Made?

The process of incorporating recycled carbon fiber into McLaren F1 cars is both meticulous and innovative. The entire process, in short, is as follows:

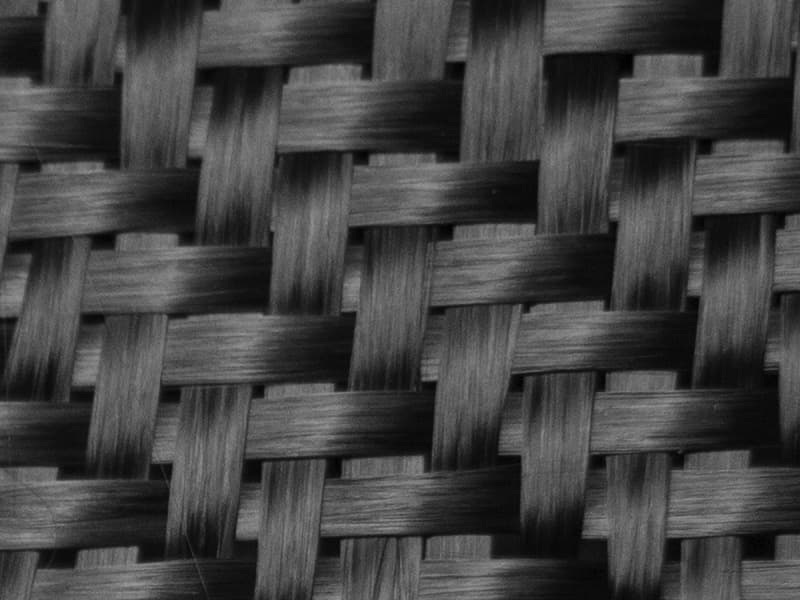

Once delivered, the carbon fiber is stored in a freezer at the McLaren factory to preserve its shelf life and maintain its optimal condition. Before the laminating process, the carbon fiber is defrosted, and a mold is used to produce the desired part.

The meticulous nature of the process involves layering thin and flexible sheets of carbon fiber to build up the thickness required for a rigid component.

Applying vacuum bags and debulks between each layer ensures a consolidated structure by eliminating gaps and air. This process is repeated multiple times, and the component is then bagged using release film to facilitate the removal of gasses. The component is finally placed in an autoclave, which uses intense pressure to fuse the layers.

This process ensures the structural integrity of the recycled carbon fiber and highlights McLaren’s commitment to maintaining the highest standards in its pursuit of sustainability.

RELATED: Carbon Fiber Sheet Made From Petroleum Waste to Revolutionize the Automotive Industry

Is Recycled Carbon Fiber as Good as New?

One might assume that recycled carbon fiber would compromise on strength and quality, but McLaren’s experience proves otherwise.

The recycled carbon fiber closely matches the properties of new carbon fiber, retaining up to 85% of its original strength. This impressive result indicates that recycled carbon fiber is not just an environmentally friendly alternative but also a viable one in terms of performance.

The feedback from those involved in the manufacturing process is overwhelmingly positive. Jacob Tidy, a Composites Apprentice at McLaren, emphasizes the impressive mechanical properties of recycled carbon fiber.

As part of his final apprenticeship project, Jacob manufactured a recycled carbon fiber component and noted that its properties were nearly identical to new carbon fiber.

This revelation opens the door to utilizing recycled carbon fiber in various car parts, demonstrating its potential for broader applications in Formula 1.

RELATED: 5 Ways to Make Carbon Fiber Car Parts Last Longer

How Did McLaren F1 Perform at the US GP?

The use of recycled carbon fiber made its on-track debut at the 2023 US Grand Prix at the Circuit of the Americas in Austin, Texas. McLaren F1, with drivers Lando Norris and Oscar Piastri, showcased the impact of this sustainable initiative.

Lando Norris managed to secure an impressive second-place finish in the overall results. This success highlights the efficacy of recycled carbon fiber in real-world racing conditions.

Specifically, the recycled carbon fiber was trialed on the cockpit branding panels of Lando and Oscar’s cars, replacing the dynamic branding panels.

Krzys Kaczmarski, Senior Sustainability Manager at McLaren, explains that using recycled carbon fiber on non-structural, non-safety critical parts is a deliberate strategy. This trial proves that recycled carbon fiber is not only environmentally responsible but also fit for purpose and sufficiently robust for use on an F1 car.

Outlook

McLaren F1’s adoption of recycled carbon fiber is not just a symbolic gesture toward sustainability; it’s a strategic move that aligns environmental consciousness with high-performance racing. The success at the 2023 US GP underscores the practicality and effectiveness of integrating recycled materials into the pinnacle of motorsport, setting a precedent for a more sustainable future in Formula 1.

As an integral component of its four-pillared sustainability strategy, McLaren endeavors to achieve a 50% reduction in greenhouse gas footprint by 2030, attaining zero waste by 2040. The ambitious plan includes expediting the shift toward a circular economy and spearheading research and development for a fully circular F1 car.

If you have questions about carbon fiber McLaren cars or any details discussed here, contact us and learn more.

Are you interested in other CARBON FIBER products? Then, visit our store and take a look at our featured collections!

Personal Accessories, Clothing Accessories, Jewelry, Home and Office, Tech, Travel, Gifts, and much more!

UP NEXT:

Read more CARBON FIBER BLOGS.

The Carbon Fiber Gear Blog is a lifestyle blog for carbon fiber enthusiasts where we talk about carbon fiber gear, fabrication, and news. In addition, we round up the most fantastic carbon fiber products, the best gift ideas, and the uses of carbon fiber.